Cold compaction and vacuum sintering of PM high speed steels (HSSs) to full density is now a well established technique [1-3]. In recent years, work has been...

Definition: The term `high speed steel' was derived from the fact that it is capable of cutting metal at a much higher rate than carbon tool steel and continues to

Our production facility, located in South Boston, Virginia, is supplied with starting material by our mill located in Kapfenberg, Austria. Beginning with top quality

as-tempered carbides of high-speed steels W3Mo2Cr4V, W6Mo5Cr4V2, and of eutectic carbides in the high-speed steels, which is about 3, 2, and 1 wt pct for

The first Matrix High Speed Steels commercially available in Japan were the YXR series produced by Hitachi Metals, Japan's leading producer (by volume) of

The first Matrix High Speed Steels commercially available in Japan were the YXR series produced by Hitachi Metals, Japan's leading producer (by volume) of

Nachi Special Steels: As an integrated producer of materials, cutting tools and bearings, Nachi We provide the best quality High-Speed Steels as ready to use.

One of the earliest applications of molybdenum was as an efficient and cost effective replacement for tungsten in tool steels and high-speed steels.

One of the earliest applications of molybdenum was as an efficient and cost effective replacement for tungsten in tool steels and high-speed steels.

an especially hard, heat-resistant steel for use in lathe tools and for other applications involving high friction and wear. Origin: 1925–30. Dictionary.com

M2 is a general purpose molybdenum high speed steel. This grade is characterized by balanced combination of abrasion resistance, toughness and good red

Few high-carbon steel tools are now available for sale in the USA (usually only from sources of used items and estate sales). High-speed steel (HSS).

Few high-carbon steel tools are now available for sale in the USA (usually only from sources of used items and estate sales). High-speed steel (HSS).

Deutsche Edelstahlwerke GmbH ranks among the world's leading producers of high-speed steels. The group of high-speed steels includes all high-alloy tool

as-tempered carbides of high-speed steels W3Mo2Cr4V, W6Mo5Cr4V2, and of eutectic carbides in the high-speed steels, which is about 3, 2, and 1 wt pct for

as-tempered carbides of high-speed steels W3Mo2Cr4V, W6Mo5Cr4V2, and of eutectic carbides in the high-speed steels, which is about 3, 2, and 1 wt pct for

powders of highest purity and adequate granulation are processed to homoge- neous and segregation-free high speed steels of virtually isotropic properties in a.

powders of highest purity and adequate granulation are processed to homoge- neous and segregation-free high speed steels of virtually isotropic properties in a.

Taylor. Special Steels Ltd. M42. M42 HIGH SPEED STEEL. C. Cr. Mo. W. Co. V. COMPOSITION. %. 1.08. 3.90. 9.40. 1.50. 8.0. 1.20. STANDARDS. AISA M42

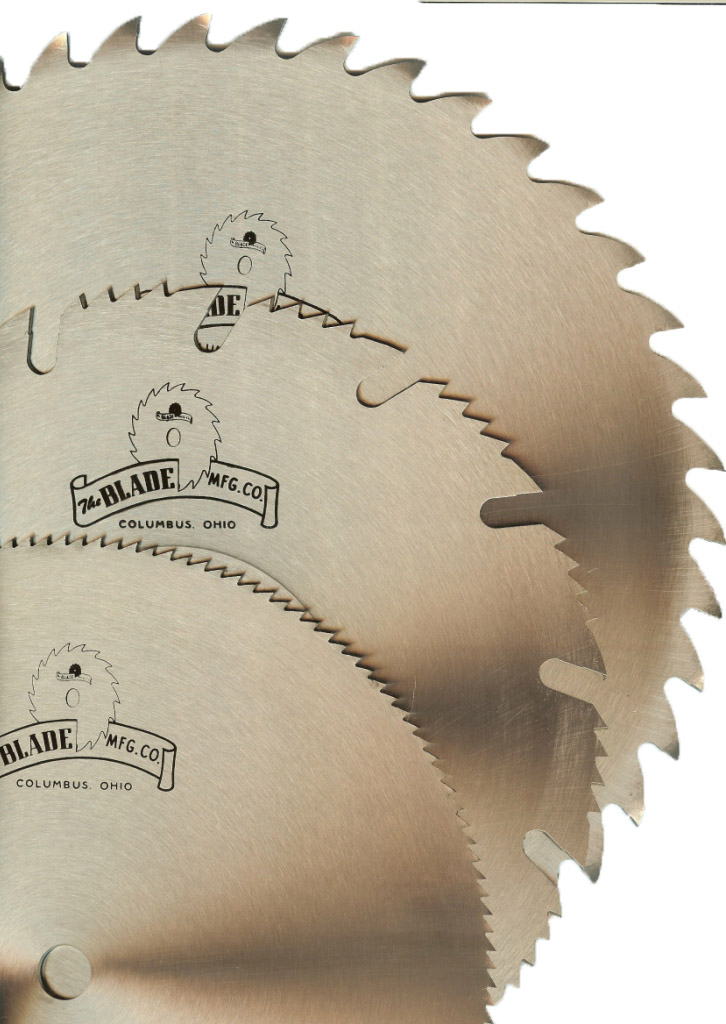

The types are, from cheapest to most expensive, Carbon Steel, Stainless Steel, High Speed Steel, Cobalt Steel, Ferro-Tic Carbide, Carbide Tipped and Solid

The types are, from cheapest to most expensive, Carbon Steel, Stainless Steel, High Speed Steel, Cobalt Steel, Ferro-Tic Carbide, Carbide Tipped and Solid

reversing roughing stands of Hot Strip. Mills. • Bending strength. • Compressive strength Rc. 3200 / 3400. MPa. SIRIUS - High Speed Steel. • Young modulus E.

When tool steels contain a combination of more than 7% tungsten, molybdenum and vanadium, along with more than 0.60% carbon, they are referred to as high

Cobalt High Speed Steel Fractional Straight Shank Jobber Length Drill Bits Features: Constructed of M-35 5 percent cobalt high speed steel for super abrasive

Cobalt High Speed Steel Fractional Straight Shank Jobber Length Drill Bits Features: Constructed of M-35 5 percent cobalt high speed steel for super abrasive

Knives made from powder metallurgy steel are relatively new. The powder metallurgy HSS steel HAP40 manufactured by Hitachi can be hardened up to

The corrosion behaviour of M2 high speed steel, as-received as well as heat-treated under different conditions, has been studied in 0.1 M KCl aqueous solution